Mark that No One is going to tell you in the water level Controller market that if you choose the wrong product, your motor will be in danger.Your motor might gets burn due to overrun in 70% Cases. But you also need to Understand Choosing a Right Product Can give new long life to your Water Pump. We will explain to you the reason that minor mistakes need to be taken care of, before buying a water level controller.

Choosing a Right Water Level can Increase Your Pump Life by 30%.[Photo] Wisely chosen Water Level also protects your Pump from getting burnt.

Dry Run Protection

If you want to install a water level controller make sure it has this protection inside it. If your Lower tank is not monitored when the Pump is on, there is 80% chance your pump will get burnt due to dry run. As low-cost water Level controllers don’t have this feature.

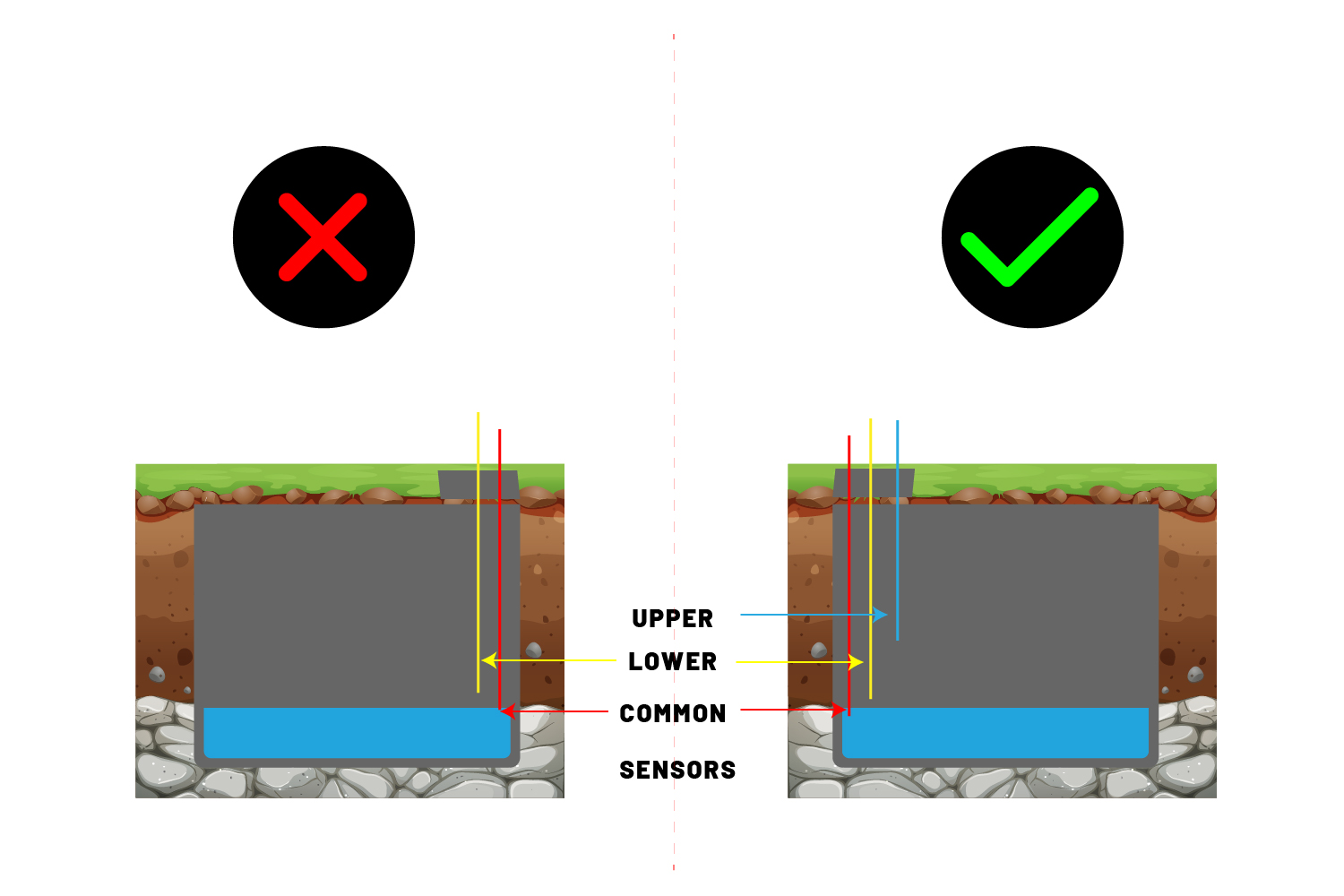

Two Sensor Sump Tank System

There is one another issue that some companies provide only One Sensor for Sump Tank dry run protection for sensing lower level only. Now what happens is that if the upper tank is empty and your water level starts to pump. And Until It gets Full, Your Sump Tank gets Empty. Here If You Have only One Sensor, When pump Stop due to gravity water inside the sump pipe comes back when the motor stops. Water Level might reach the sensor in milliliters and again and it will start the pump. After a few seconds again. We have seen this situation where it keeps the motor on-off for hours. And Your Motor Gets Damaged.

Here one might argue that, what if someone has programmatically set to run motor for a few more seconds, so this doesn’t happen. But even in that case, when water comes the next day, the pump will get a start and stop when the sump tank is filling slow. And your Upper tank is filling fast using a pump. So we prefer to have two sump tank sensors. In Two Sensor System for Sump tank, One Lower Sensor Act as Stop Motor Signal, and Upper Sensor Works as Star Motor Signal. If the Sump gets empty, It will not restart the motor until it touches a high sensor set at 30%.

Low-Cost System

Cheap Water Level Controllers have compromised components to match low cost. There are many components which can easily reduce device cost by half, like low capacity relay, Logic ICs, Cheap SMPS, Reused Plastic Enclosures and many more.

Relay:- When Purchasing WLC look for its Relay Rating and Company. Is it a Good Brand? Leone, Tara, Goodsky, Panasonic and few other brands are commonly used in India. And Also you have to look for your motor load and relay ampere rating. Normally any 0.5 HP motor takes load upto 2A when the motor is well serviced or new and could take up to 6A in initial jerks or Chock Up rotor while bearing is too old for many more reasons. Now If your Motor is of 1 H.P. Motor Load goes upto 12A. Now you will see many companies claiming to work their 10A Load Relay upto 1.5HP Motor. In Normal days it might work well, but when current goes beyond the relay rated current system might get burned and damage other aparus in line.

Switches & Connectors:- Most Cheap Products come with Cheap 5A Switches and low Rating Connectors. This Switches and connectors melts while exceeding its rated current. We all Know Good Products require Good Quality and Quality Comes with Price Only. While our mindset of getting quality products at the cheapest price.

Reused Components:- Reused Components you can get at one fifth price. Yes Many Internal Components like Transformers, or SMPS which makes product cost too less.Even Plastic O which product is enclosed, which is not virgin and used plastic are less durable and sunlight can damage it very soon.

Logic & Functionality

Simple Water Level controllers used to work on simply comparator based logic where voltage measurements are compared for their respective level and changes on voltage trigger ON OFF actions. Where right now WLC are made of Microcontroller with complex logic which works more accurately and tends to protect the system in uncertain conditions which could be predefined.

Getting the latest MCU based Controller is more accurate if written well. Now one wonders how this makes a difference with the old Systems.

- With MCU we can monitor Actual Load pump is taking.

- Pump maximum running time could be saved and stop the motor while over run.

- Delayed start and stop could also be applied with MCU for many purposes. This could Prevent on multi floor homes and buildings where if the motor once stopped and rapidly starts again n on second due to power cut or any other reason.Water in the pipe back Force while pump is pushing upwards makes pump gets burned.

- Sensor Abnormality could also be prevented with MCU logic. And there are Thousand more functions you can achieve with MCU-Microcontroller Based Systems.