Water Level Controller is the best water-saving technology people have started using in the past decade. Though many companies have started also evolving from simple 555 based controlling to MCU based controllers and now artificial intelligence is taking place in all around with Industry 4.0 Concept. We need to understand how to find best automatic water level controller is doing basically and technological difference we need to know before purchasing water level controller online.

WHAT IS WATER LEVEL CONTROLLER?

A Simple Water Level Controller is basic Motor ON-OFF switch Replacement that you are doing each day manually when your overhead tank gets empty.This mechanism starts the motor when upper tank level gets empty and it stops motor, when tank is full. Now Level Controllers are available in many varieties and names starting from just 250 Rs. to 10,000 Rs. Now We might thave question that what should I choose? And What is Better for my Motor Type? We, Will, make you Understand What are the Five Most basic Things you need to understand Before Buying Water Level Controllers?

Facts No One Is Telling You !!!

Mark that No One is going to tell you in water level Controller industry that if you choose a wrong product, your motor will be in danger. If your motor gets burned due to overrun, you can not imagine that in 70%(Yes-Seventy Percent) Cases water level controller is the reason, which needs to blame. But you also need to Understand Choosing a Right Product Can give new long life to your Water Motor. We will explain you the reason that what minor mistakes need to be taken care of before buying a water level controller.Refer Our Detailed Article on Thing t Know about Cheap Water Level Controller

1)- Understand Your Motor

There are Two Types of AC Water Motor in normal duplex houses up to 3th floor.

- Jet Pump- Out Side Sump Tank

- Submersible Pump- Inside Sump Tank drawn inside water

Now we need to understand that each motor is consuming different power depending on different conditions like 1.- Distance between sump tank, Overhead tank, and motor 2.- It depends on Pipe Tickneness and Pipe arrangement from bottom to top 3.- Motor’s rotor friction,years of environmental Conditions, Metal used in motor,copper quality used in winding,rusting, etc.You need to Check Your Motor’s Existing Power Consumption and when it needs a service.

Check Your Motor’s Existing Power Consumption if possible using Clamp Meter

Water Level Controller Comes with Motor Load or power specified, and it might be possible that your old motor is taking more load than it is needed. We have seen that 0.5 HP motor is taking load of 5A, which is almost 1.0 HP motor is taking in normal condition. Or 1.0 HP Motor is taking up to 9 Amps with 12A Starting Jerk. Now if any Water Level Controller is capable of running with 1.0 HP motor, due to heavy load, In few Month, your controller may cause some issues as all internal components right from connectors to relay to internal wiring is designed accordingly.

For that You can Refer our blog Water Motor Buying Guide for Home.

2)- Water Quality

Every 100 Km, Water Quality is different in India. Water Quality also differ with seasons, and you nee to understand that water might look fresh, but it can damage your sensor in long run. Now for that We Need first to Check Water Clarity that is there any small visible impurities like mud or dust can be seen if we take clear bottle and analyze it.If it is too much dust particle you need to choose sensor accordingly. As Contact Type Sensor attracts dust and small particles when Direct Current flows inside sensor and in three months to one Year your sensor will get covered by dust and won’t work effectively.

Check Water Clearity and Hardness

Second Taste your water, and if taste like bottled water or RO Water it is okay,and if Your Water taste salty than you need to consider that when current passed through it it will attach minerals and at long-run scale depositing on steel rod which will worsen the case as sensor will not be sense water level effectively.

Now take note that taking alternate costly magnetic sensor won’t help all time as they also have some advantages and disadvantages which we will discuss in further post.There are many guides already available on youtube for testing water hardness.

Now take note that taking alternate costly magnetic sensor won’t help all time as they also have some advantages and disadvantages which we will discuss in further post.There are many guides already available on youtube for testing water hardness.

3)- Water Level Controlling Method

Water Level Controllers works on same sensing techniques but behaves differently according to their programs. Most Of those WaterLevel Controller Run On Comparator based circuit which is start motor as soon as it detects 0-0 Condition on OverHead Tanks. Now keep that in mind that it is always recommended to use DRY RUN Protected Water Level Controller as without dry-run protection it is better to not install water level controller at all.Why- Because Dry run Protected Water Level Controller doesn’t allow the motor to run dry when there s no water in the sump tank and switch off the motor at the right time. Without Dry run, it is guaranteed that in the near future your motor might get burn.

Dry Run Protectction is Most Important of All

How Cool is that, if any water level system analyzes your motor running time and if a motor runs more than it required it stops the pump automatically, or we have the option to choose optimal running time for a motor run. Yes look for the feature available with water Level controller rather than just price as in the long run, its durability and features only going to save your motor.

4)- Sensor Type and Market Sensor Availability

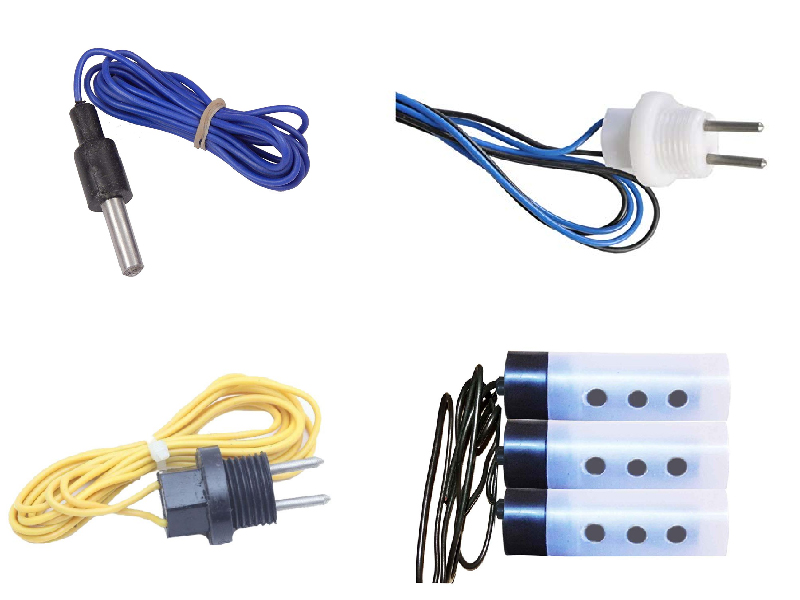

First, we have to understand which type of sensors supported by your water-level-controller. Select a Universal Sensor Supported water-level-controllers. Now how can you know which water level is supporting contact and non-contact both type sensor? If Any Company’s sensor is working with contact type or steel probe usually supports all other kinds of the sensor. Few Companies also sells Down switch sensor, which is not in very common, and you need to purchase maintenance-freely, which are rarely available near to your electrical shop, better avoid buying them. You can ask directly a shop or online dealer that is your controller supports rode type sensor, and you will have your answer. There Is Basic Two Type of sensor or water Level Measurement: Contact Type & Non-Contact Type. Now Contact type sensors are low cost, more sturdy and easy maintenance where non-contact type sensors are high cost, delicate and No maintenance.Which sensor to use is totally depends on water quality and personal usage. As Contact Type Sensor is more rigid whereas the non-contact type sensor has glass-reed-switch or electronic parts inside it which are easily damageable.

Contact Type Sensor

It is recommendable to use STAINLESS STEEL 316 for contact-type sensors. Contact Type sensor is highly durable and easy to maintain as you can clean them frequently once a year using sandpaper to remove deposits scale.

Before buying contact type sensor please look at the wire joint with Stainless steel Probe, is it sealed or screw type? It is recommended to use a sealed wire joint sensor as scale will deposit starts mostly from two metal joint. The sensor is having more life because when two different metal joint it needs refitting or reattaching wire at a certain time. Contact type sensor needs little bit maintenance depending upon your water quality as scale deposits happen due to Minor Direct Current passing through It for checking connectivity. Scale Deposition is varying from home-to-home, but we can easily clean any scale with an iron brush or sandpaper in just two minutes. Contact Type Sensor Scaling also highly dependent on Internal Circuit and can use easily maintenance-free if designed well. For that Refer our sensor test blog in upcoming days.

Non-Contact Type Sensor

Now talking about Non-contact type sensor, there are many type reed switch-based magnetic float sensor, ultra-sonic sensor, float switch sensor. Cheapest among them is Reed Switch based Magnetic Float Sensor. It might cost four times the contact type sensor.

Magnetic Float Switch Sensor which uses Gold Plated Reed Switch or German Make Switch last longer than the cheap china white magnetic float switch sensor widely available sensor. This sensor uses a glass switch and needs gentle care while cleaning tanks. Otherwise this type of sensor is long-lasting and maintenance-free. There is also a float type ball sensor, which is varying quality and can not judge how much will it be going to last. It is better to go with magnetic float switch sensor rather than ball type sensor. And Ultra Sonic sensor is Application, And Water Level Controller Specific as Very rare WLC are providing them, and too high cost for replacing due to internal circuit damaged or water damage. Float switch sensor using a different kind of Plastic Material and before buying them study material is virgin and properly sealed from water.

5)- Material Used

Switches: Please look at switches used to operate Manual-ON-OFF. Do you find them long-lasting and good quality? If You have physical touch option available try to ON-Off Fast, Do you find will it going to survive five years without any issue. Please Make sure the product is visibly sturdy. Connectors: Also Inspect Connector type, which is used to connect Motor Connection and Sensor Connection. It is advisable to compare Connector type. Relay and Contact Rating: Please also see ampere rating and choose External Case:External case of PC and ABS are a good choice, and there are a variety of choices available.

Coming to an end,Each Topic needs a better explanation with separate blog, please contact me via [email protected] or [email protected] for better any guidance.